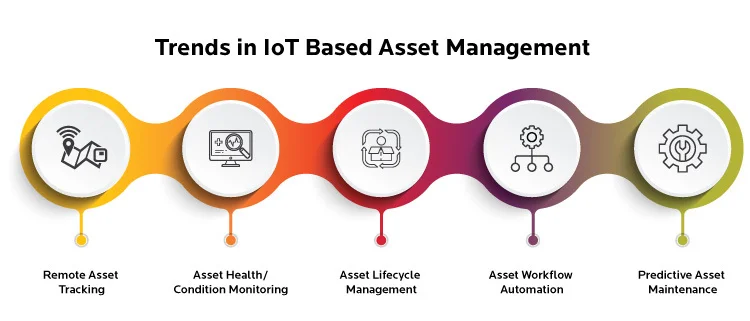

IoT Asset Management Use Cases

Traditionally driven by innovation, the

manufacturing industry is now undergoing the ‘Industry 4.0’ revolution. Disruptive technological growth in manufacturing, enhanced by modern sensors, robotics, drives, and actuators, has infused a revolution in the supply chain, transportation, communication, housing, energy, production, and asset management. Asset management is a prominent area to focus on influences the overall workflow and processes. In this light, let us look at a few use cases where IoT solutions help in improved asset management:

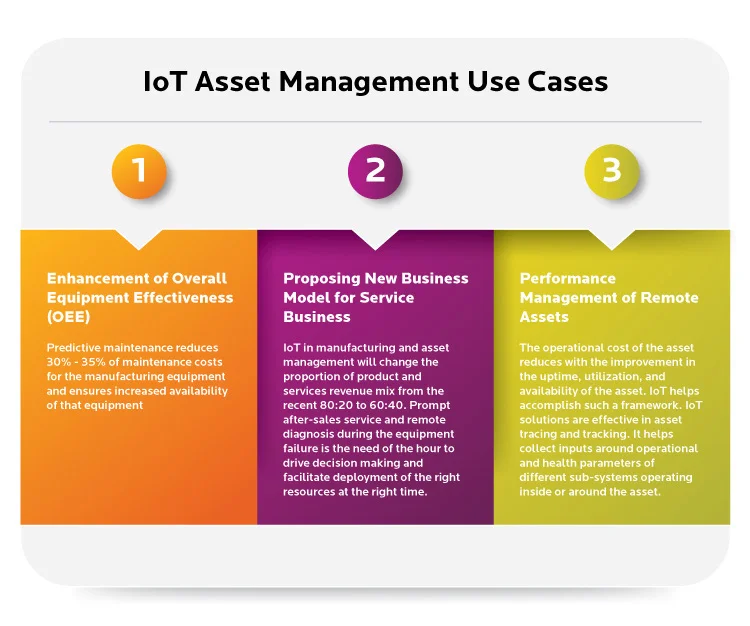

Enhancement of Overall Equipment Effectiveness (OEE)

OEE is one of the essential metrics to measure a plant’s efficiency. Failure or scheduled breakdown and maintenance weigh heavily on the equipment availability.

Plant maintenance becomes a priority to ensure availability and almost no downtime of manufacturing plants. Instead of scheduled and preventive maintenance, direct data collection from the equipment, historical data maintenance, and inputs from OEMs can now be predicted with the help of IoT-enabled solutions. Hence, predictive maintenance reduces 30% - 35% of maintenance costs for the manufacturing equipment and ensures increased availability of that equipment.

Proposing New Business Model for Service Business

IoT in manufacturing and asset management will change the proportion of product and services revenue mix from the recent 80:20 to 60:40. Prompt after-sales service and remote diagnosis during the equipment failure is the need of the hour to drive decision making and facilitate deployment of the right resources at the right time. These changes induce reduced downtime and decreased cost in areas of support, warranty & mobility.

Leveraging IoT technology and operational data metrics, manufacturers now can innovate outcome-enabled service models and ensure greater chances of equipment. Manufacturers can now offer models based on rentals instead of selling the entire product to the customers.

Besides, the asset management group can use the feedback from the quality assurance team for taking corrective measures in the subsequent product releases, thereby reducing the development and testing time.

Performance Management of Remote Assets

The operational cost of the asset reduces with the improvement in the uptime, utilization, and availability of the asset. IoT helps accomplish such a framework. IoT solutions are effective in asset tracing and tracking. It helps collect inputs around operational and health parameters of different sub-systems operating inside or around the asset.

With these additional data made available, one can achieve higher asset utilization and uptime through predictive maintenance and usage. Additionally, external parameters assist in the in-depth analysis of the patterns of use that drive strategic decisions like buying and renting these assets. This could open more opportunities for the equipment vendor.

IoT Asset Management Use Cases

Click to zoom in

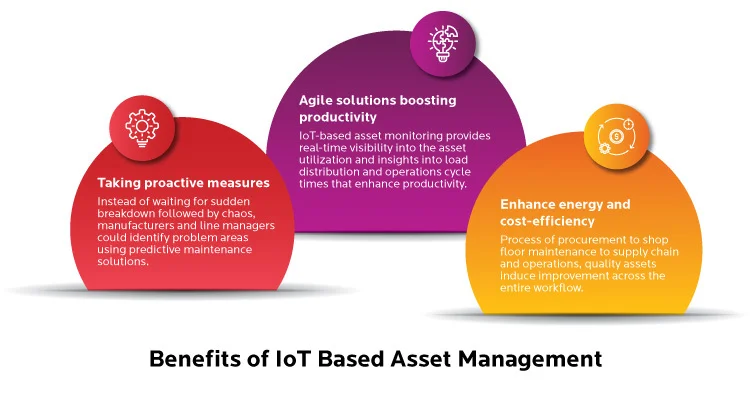

Benefits of IoT Based Asset Management

Empowering software stack with

Industrial Internet of Things (IIoT) and applications for predictive analytics, 5G connectivity, artificial intelligence, machine learning, and edge computing prove valuable assets for manufacturers. However, for many manufacturing companies, technology selection is the easiest part, while value capture, use case identification, and scalability are the major challenging areas. Implementation of IoT could help streamline the entire asset management process, helping businesses to stay competitive. Here are some of the benefits for IoT based asset management:

Taking proactive measures

Instead of waiting for sudden breakdown followed by chaos, manufacturers and line managers could identify problem areas using predictive maintenance solutions.

Agile solutions boosting productivity

IoT-based asset monitoring provides real-time visibility into the asset utilization and insights into load distribution and operations cycle times that enhance productivity.

Enhance energy and cost-efficiency

Process of procurement to shop floor maintenance to supply chain and operations, quality assets induce improvement across the entire workflow.

Benefits of Building Connected Factories

Click to zoom in

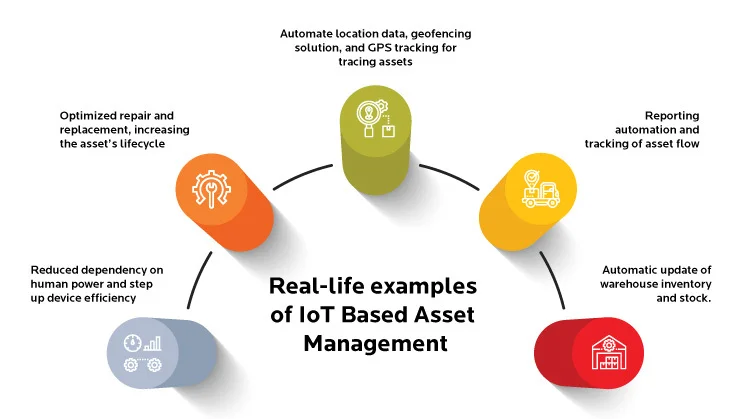

Real-life examples of IoT Based Asset Management

- Reduced dependency on human power and step up device efficiency: IoT can automate the end-to-end process and continuously share asset status, health, and other parameters with the centralized system.

- Optimized repair and replacement, increasing the asset’s lifecycle: Using predictive maintenance sensors to track data performance and prevent sudden machine failure.

- Automate location data, geofencing solution, and GPS tracking for tracing assets: While on the move, tracking locations to identify and fix hidden losses and roadblocks.

- Reporting automation and tracking of asset flow: Consistent and automatic tracking of the parts used to produce the assets.

- Automatic update of warehouse inventory and stock: Staying alert on the inventory stocks and replenishment to avoid going out of stock at any given point in time.

Real-life examples of IoT Based Asset Management

Click to zoom in

Metrics to Track the Efficacy Of Asset Management With IoT

- Overall Equipment Effectiveness (OEE): OEE is the most common metric to track plant efficiency and is a part of every plant manager’s KPI. It identifies the percentage of highly productive manufacturing time within the entire process. By measuring OEE, manufacturers would gain significant insights on how to be at their productive best

- Asset uptime and downtime: This is one of the most crucial metrics to reduce maintenance costs. The aim here is to study the data carefully to increase uptime, reduce downtime, thus, leading to optimal utilization.

- Cost efficiency and Asset Optimization: Opex is reduced by preventive maintenance, and Capex is reduced by improving the lifecycle of the machine and better utilizing the assets.