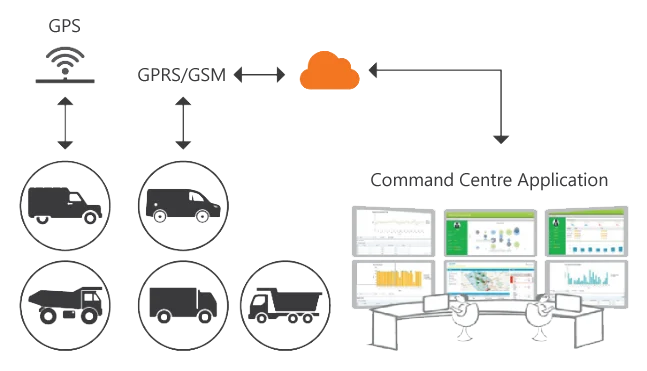

Businesses (irrespective of the industry or domain) now consider IoT to be one of their key strategic technology initiative that can help them in a range of scenarios including improving customer experience, physical asset tracking, optimizing processes, and providing better visibility into operations, among others.

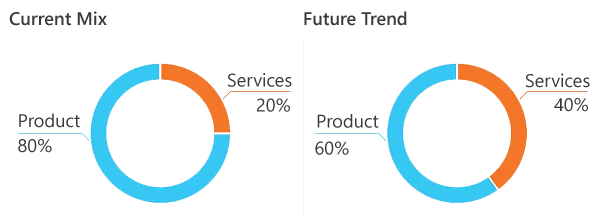

The growth potential of IoT-related products and services is immense in today's market scenario and future as well. IoT product and service providers are expected to generate an estimated incremental revenue of $300+ billion by 20201 and that the worldwide market for IoT solutions will grow from $1.9 trillion in 2013 to $7.1 trillion by 20202 . Furthermore, the installed base of IoT devices will grow at a CAGR of 17.5% to 28.1 billion during the same period.

IoT in Manufacturing

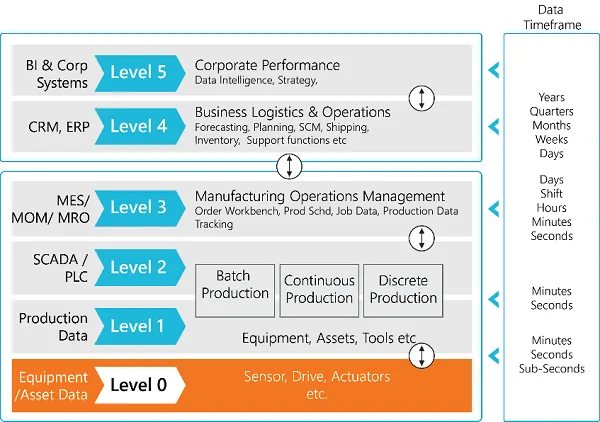

IoT is transforming the way organizations in different industries are doing business including the manufacturing companies. Till now technology has been used primarily for running the business and managing manufacturing operations, for automating processes and for collecting data related to assembly jobs. However, IoT goes well beyond this to next level for data collection.

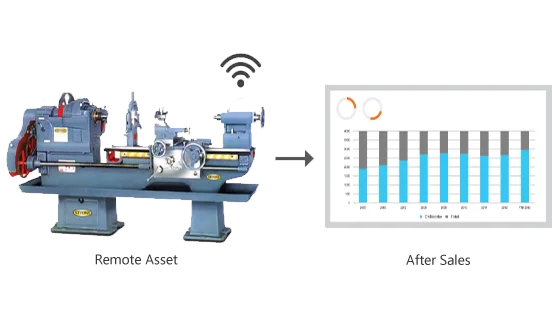

IoT aids in the collection of data from different 'Things' - about operations, production, quality, utilization, consumption, etc. and uses it to streamline and refine the business processes.