Pillar 2 – Technology and Infrastructure

It is rare for an organization to have or develop all the technological capabilities needed to embark on its Smart Manufacturing journey from scratch. However, by embracing the mutually complementary technology with ecosystem participants, the organization and other participants stand a better chance of creating successful connected products. Another aspect is the presence of open technology infrastructure and interfaces that can help integrate various technologies.

This is where a partner like Birlasoft can help you get started.

intelliAsset for Silos - For safer RMX Operations, Customer Excellence and Process Efficiency

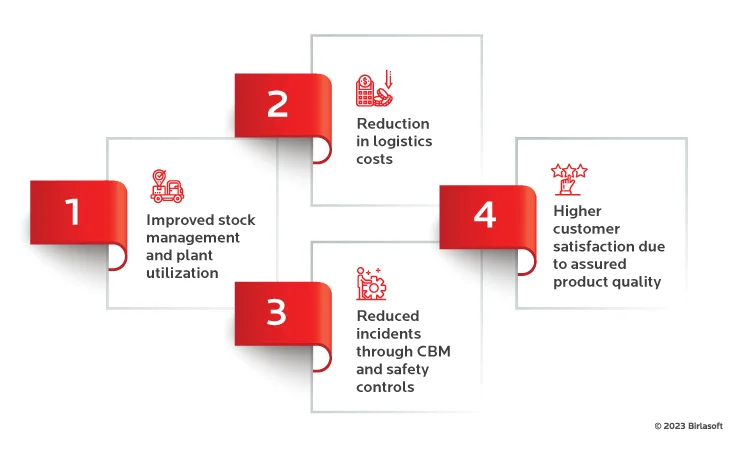

Birlasoft enabled a Global Building Materials Company to drive customer excellence, optimize operational efficiency, and improve employee health and safety with the IntelliAsset for Silos Solution, developed on an Industrial IoT Platform. A critical part of their supply chain has been automated with this solution – including timely delivery of cement to RMX plants, automated re-ordering, driver behavior tracking, and fleet optimization. The other advantages include the following:

- Efficient Stock Utilization and Management: Integration with various EBM systems and data collection from the control layer

- Continuous monitoring of critical sensors, scalable data acquisition, and streaming: high velocity, volume, and a variety of near-to-real-time data

- Automated cement ordering and tracking: re-ordering based on cement level, weather conditions, lead-time, demand and consumption patterns, etc.

- Maintenance Scheduling and Monitoring: Monitor maintenance schedule and automatically capture maintenance records for critical equipment

- Data Analytics and Representation: Monitor cement stock levels, replenishment analytics, and production plant utilization dashboard

- Health and Safety Improvement: Eliminate operational risks related to unloading material from the truck to iSilo, regardless of the unloading point

- Machine Learning for Replenishment and Logistics Costs Optimization: ML ‘agent’ using the reinforcement learning technique to order the cement and push as many orders as possible to non-working hours

Solution Impact

Click to zoom in

Pillar 3 – Data Sharing

While data is the most valuable asset in an ecosystem, there should be a proper framework to access, use and share data across partners. A system of data governance must be in place to ensure confidentiality, trust, and privacy.

With access to large amounts of data generated through the ecosystem, the organization can extract value from massive real-time data using AI/ML models and draw better insights. Data is extremely important in some cases, such as the Digital Twin, where data inputs from multiple participants of the ecosystem are required.

However, a complete understanding is required of what type of data can be accessed, by whom, and until when, while ensuring that the key Intellectual Property of the participants is protected.

Leveraging Ecosystems to enhance Agility and Flexibility

Having an ecosystem in place can also help manufacturers speed up and scale their Smart Manufacturing initiatives and allow organizations to embark on more innovative and challenging initiatives and transformations. This helps the organization become more agile, flexible, and driven. The presence of an ecosystem with varied participants can also help create diverse solutions to various business cases and gain a broader perspective. Consequently, an organization can also gain new partnerships and insights through the ecosystem and expand organically.

With predictable production and integrated Demand Management powered by an IIoT-driven ecosystem, manufacturers can enhance revenue with a better customer experience and new business models. They can accelerate operations and efficiency with enhanced workplace safety and green energy monitoring while exerting control on asset utilization and uptime for improved reliability and maintenance. Within an ecosystem, manufacturers can also look toward reducing transaction costs and also reduce risk.

A Framework for the Ecosystem Approach

Some points to be considered while building an ecosystem are:

- A basic analysis to decide what types of ecosystem participants the organization would have to work with in order to create a technology/capability pool that is complementary to the current internal capabilities.

- Assignment of roles and responsibilities to different participants in the ecosystem and incentives/propositions for their continued support. This may involve creating a roadmap for the journey forward.

- Expectation setting of what is possible and what is beyond the scope.

- Striking a balance between knowledge sharing and protecting key IP while creating connected products.

- A way to ensure that no participant in the ecosystem takes undue advantage of their position. Instead, what is required is holistic growth. However, if the relationship is asymmetric, some conditions need to be agreed upon and implemented.

- Mutual training and networking between participants to strengthen the ecosystem and network effect.