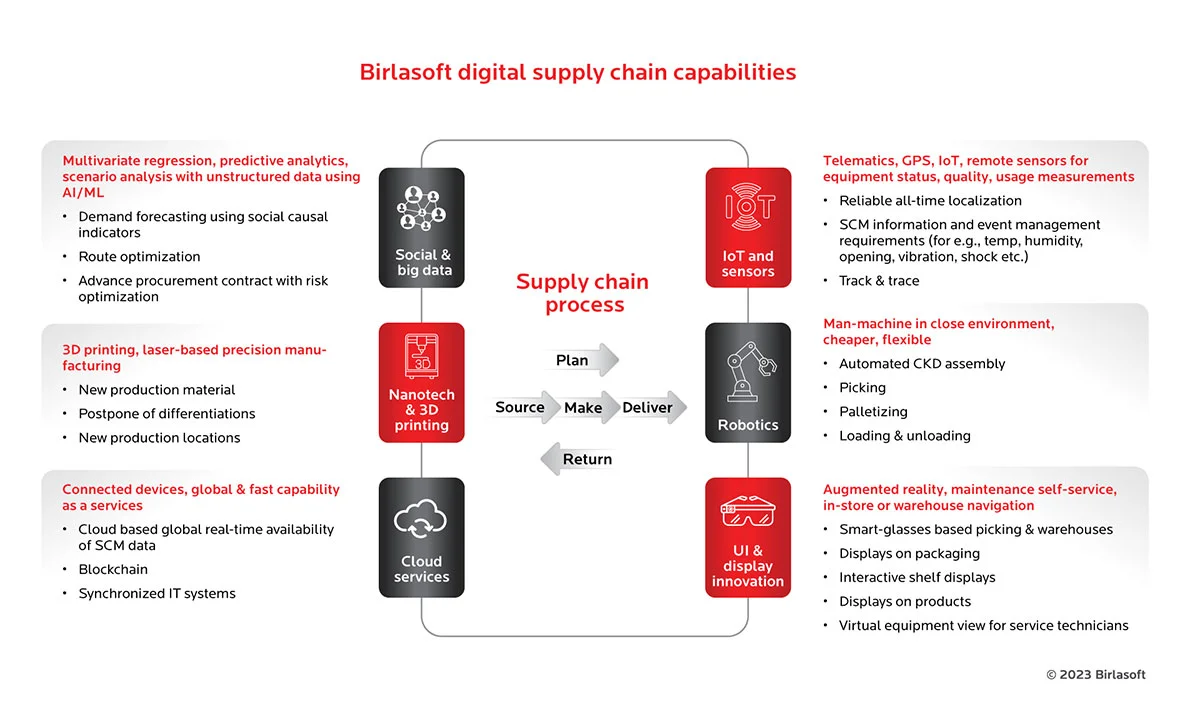

- IoT and Sensors: IoT devices and sensors are the backbones of the digital supply chain, providing real-time data that allows organizations to make informed decisions. For example, IoT-enabled devices can monitor the temperature and humidity of products in transit, ensuring they are transported under optimal conditions. Sensors can also monitor the wear and tear of equipment in a factory, enabling maintenance to be performed before a breakdown occurs.

- Social and Big Data: This is a key enabler in the digital supply chain, providing valuable insights into customer behavior and preferences. We can analyze this data to identify trends, improve customer engagement, and streamline operations. For example, social media can gauge customer satisfaction, while big data can optimize delivery routes and reduce transportation costs.

- Nanotechnology and Printing: Nanotechnology and 3D printing are changing the game in the digital supply chain, providing new ways to produce and deliver products. Nanotechnology can develop new materials with improved strength, durability, and thermal resistance, while 3D printing allows for the creation of customized products in real time. This technology can potentially make the supply chain more efficient and sustainable.

- Cloud Services: Cloud computing has transformed how organizations to store, manage and analyze data. The cloud enables organizations to access the information they need, when needed, from anywhere in the world. This is particularly useful for companies with multiple locations, as it allows them to coordinate their supply chain efforts and make informed decisions.

- UI and Display Innovation: Advances in the user interface (UI) and display technology are making it easier for organizations to monitor and control their supply chain. For example, interactive displays can provide real-time information on the status of products in transit, while UI innovations can make it easier to access data and make informed decisions.

- Robotics: Robotics is changing the way products are manufactured and delivered. Automated systems can perform repetitive tasks more efficiently than human workers can, freeing up resources for other important tasks. Robots can also monitor and control the supply chain, ensuring everything runs smoothly and efficiently.

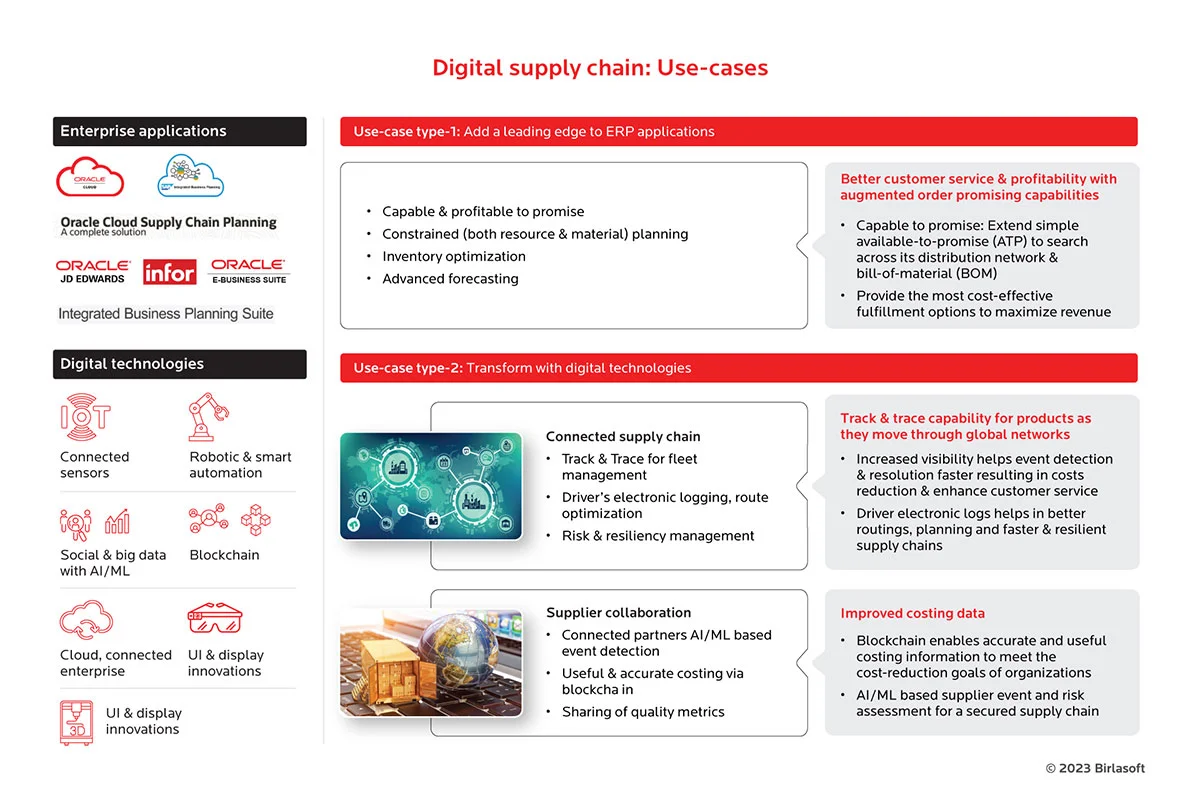

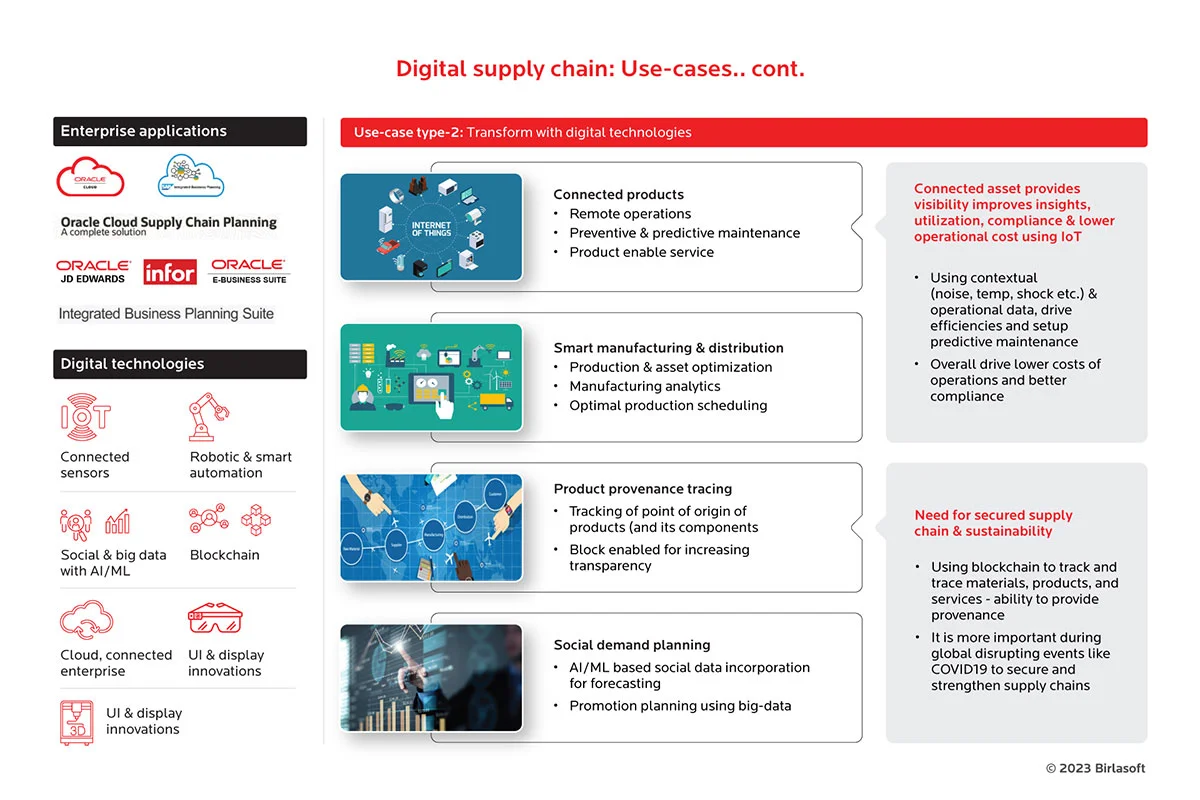

Birlasoft is at the forefront of the digital supply chain, offering a comprehensive array of enterprise solutions such as Oracle Cloud, Oracle EBS & JDE, Peoplesoft, Microsoft, and Infor to meet all your supply chain needs, no matter your industry.