Bring Industry 4.0 to Life With

Modern manufacturers like you need to be agile and efficient in this challenging and volatile industry. And to that end, we help you maximize supply chain visibility, streamline your shop floor operations, and foster sustainable manufacturing. To that end, we are committed to helping you break barriers and achieve high-velocity manufacturing with process science, industry 4.0, and core manufacturing systems.

Insights

Ideas that help you ace manufacturing

Top Offerings

Choose from a wide variety of offerings to meet your business needs.

Supply Chain Analytics & Risk Management

De-risk your supply chain with our supply chain visibility and resilience focused solutions.

Warehouse Management

Automate your warehouse management with our AI and AR powered solutions. Take full control of your logistics with our end-to-end logistics visibility solutions.

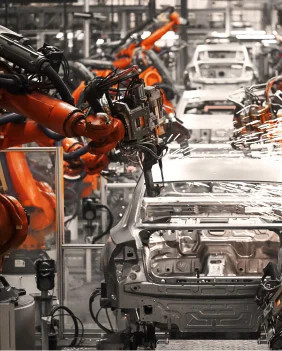

Shop Floor Modernization

Drive real time plant and shop floor visibility with our smart manufacturing and asset management solutions.

Workplace, Workforce & Environment Management

Foster safe and compliant workplaces with contact tracing, collision avoidance autonomous vehicle, and AR powered solutions.

After Sales & Customer Service

Drive sales and customer service excellence with our field servicing, remote collaboration, and CRM powered solutions.

Featured Solutions

Explore these digital solutions that have transformed manufacturing for our clients.

Track shop floor assets real-time for higher productivity, production uptime, and cost reduction with this award-winning solution.

Minimize supplier risk exposure and build disruption-free supply chains with this AI-powered preventive risk mitigation solution.

Dealer Connect

Bring your dealer and sales network closer to achieve fast sales growth at-scale with this solution.

MFGEdge

Achieve faster time to market & reduced TCO using this pre-configured SAP package solution.

4Sight

Improve your demand fulfilment with this AI powered forecasting solution.

Kitting & Production scheduling

Optimize your resource usage, reduce inventory costs, and optimize your production and scheduling with this Oracle-powered solution.

Looking for a technology solution to fix your upcoming manufacturing challenge?

Our industry 4.0 and manufacturing domain gurus are ready to help you out.

Talk to us today.

Success Stories

Don’t take our word for it. See how we have transformed businesses worldwide.

Why Choose Birlasoft?

Our client work speaks for itself. But there are more reasons to partner with us.

The CK Birla Heritage – Leveraging Group’s Manufacturing history of 170 years

Most preferred partner for core manufacturing system rollouts

Digital consulting powerhouse to build next-gen manufacturing solutions

Award-winning nimble and effective industry 4.0 solutions to fix your core manufacturing problems

Partnerships

FAQs

Industrial manufacturing involves the production of goods using machinery, tools, and labor. It encompasses a wide range of industries, including automotive, aerospace, electronics, and more, focusing on mass production and efficiency.

Digital transformation in industrial manufacturing can lead to improved efficiency, reduced costs, and enhanced product quality. By integrating technologies like IoT, AI, and big data analytics, manufacturers can optimize their operations and gain real-time insight.

Manufacturers can implement Industry 4.0 solutions by adopting a phased approach. This involves assessing current maturity state & capabilities, identifying areas for improvement, investing in relevant technologies, and training the workforce. Partnering with experts in digital transformation can also facilitate a smoother transition.

- Implement lean manufacturing principles

- Use automation and robotics

- Optimize supply chain and inventory management

- Train employees for advanced technologies.

Industrial manufacturers face challenges such as supply chain disruptions, rising material costs, mass customization , labor shortages, and the need for continuous innovation. Addressing these challenges requires strategic planning and the adoption of advanced technologies.

Flexible manufacturing systems (FMS) allow factories to quickly adapt to changes in product design or volume without significant downtime.