Emerging technologies are reshaping industrial production, giving rise to the "Plants of the future." To bring this vision to life, manufacturers need strategic leadership, skilled employees, and robust IT infrastructure. It's a transformative journey where adaptability and forward-thinking drive the factories of tomorrow.

Martin Marietta achieves JDE Consolidation & Upgrade with Zero Downtime

Key Industry Challenges

We expedite manufacturers' progression toward crafting future-ready plants by re-envisioning their business models, revamping product lifecycles, digitalizing manufacturing operations, and delivering top-tier stakeholder experiences for shopfloor workers, supervisors, leaders, and suppliers.

- Accelerating operation excellence value

- Elevating Performance through Real-time Visibility and IT-OT Synergy

- Enhancing process robustness and plant reliability

- Shortening operator training time with guided assistance

- Cutting costs in inventory, quality, production, and maintenance

- Reducing carbon footprint across operations and enterprise

Value Creation

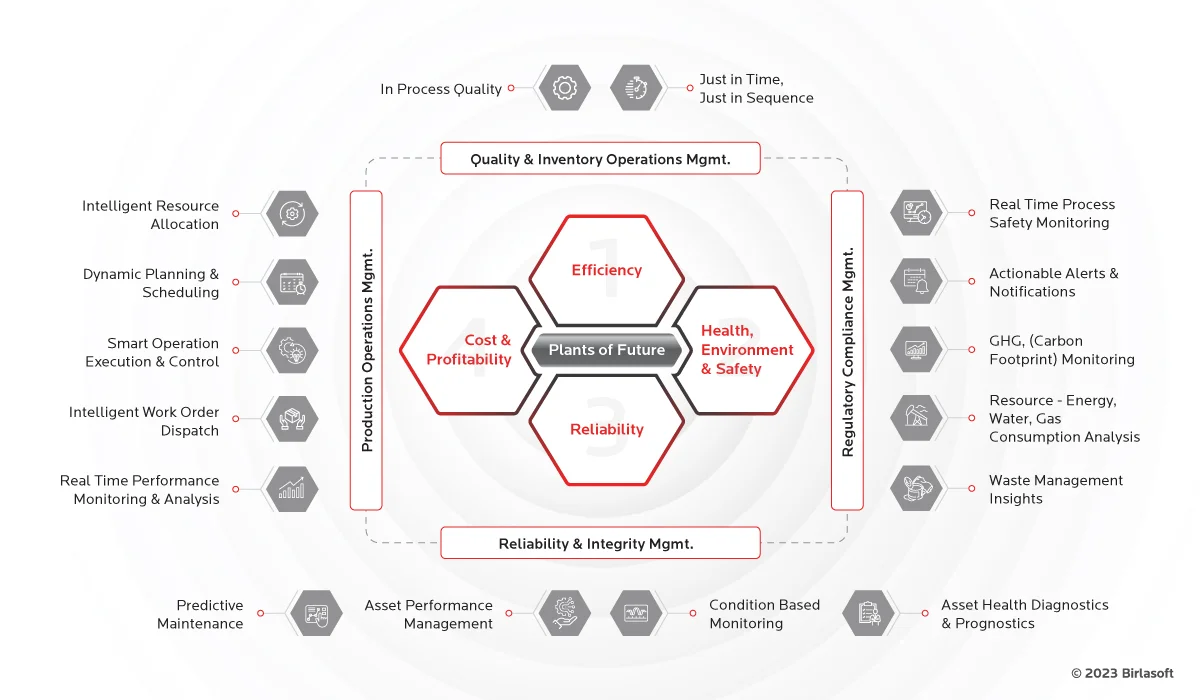

Key to Achieve Digital Manufacturing Excellence in Plants

To achieve digital manufacturing excellence in plants, we focus on key success measures. Our approach ensures enhanced efficiency, cost-effectiveness, and improved profitability through optimized processes. We prioritize health, environment, and safety standards, ensuring sustainable practices. Furthermore, we bolster sustainability, minimizing downtime while maximizing the production. These pillars form the foundation of our commitment to excellence in digital manufacturing.

We gauge maturity using Birlasoft TRU Smart Factory Assessment Framework and pave the way to peak IT-OT excellence.

Top Offerings

Delivering advanced solutions such as real-time shop floor visibility, supply chain resilience, interconnected operations, and enhanced asset performance through our connected products.

Shop floor real-time visibility & automation

Achieve operational precision with our advanced solutions, offering real-time insights into your shop floor activities while automating key processes for efficiency.

Building resilient supply chains with end-to-end visibility

Strengthen your supply chain's resilience with our comprehensive visibility solutions, ensuring you have complete control and transparency from suppliers to customers.

Connected operations and smart factory

Seamlessly integrate your operations into a smart factory ecosystem, optimizing processes, reducing downtime, and enhancing productivity through interconnected technologies.

Asset performance management with connected products

Asset performance management with connected products: Maximize asset efficiency and longevity with our connected product solutions, providing actionable insights and predictive maintenance capabilities for superior asset performance.

Featured Solutions

Discover our advanced solutions, revolutionizing manufacturing processes for heightened operational efficiency. From Intelliasset optimizing asset performance to Prodlogix and Machine Logix enabling data-driven decisions, our seamlessly integrated solutions craft a future-ready manufacturing ecosystem. Together, they establish the groundwork for a connected and innovative manufacturing landscape.

Track shop floor assets real-time for higher productivity, production uptime, and cost reduction with this award-winning solution.

Minimize supplier risk exposure and build disruption-free supply chains with this AI-powered preventive risk mitigation solution.

Minimize supplier risk exposure and build disruption-free supply chains with this AI-powered preventive risk mitigation solution.

Success Stories

Why Choose Birlasoft?

Domain expertise: With the TRU Smart Factory Assessment Framework, we evaluate your maturity and chart a path towards achieving peak IT-OT excellence

Proven success: Backed by success stories from Fortune 100 and 500 manufacturers, showcasing tangible results

Strategic alliances: We have strategic partnerships in worker safety and decarbonization, ensuring comprehensive solutions

To know more about Birlasoft's comprehensive services, contact us

FAQs

"Plants of the Future" refer to advanced manufacturing facilities that leverage emerging technologies to enhance production efficiency, agility, and sustainability. These plants integrate digital solutions, such as real-time visibility, IT-OT synergy, and connected products, to optimize operations and reduce downtime.

Birlasoft aids in the transformation towards "Factories of the Future" by re-envisioning business models, digitalizing manufacturing operations, and enhancing stakeholder experiences. Their solutions focus on real-time shop floor visibility, supply chain resilience, and asset performance management.

Key technologies include digital twins, predictive & Prescriptive analytics, Robotic & Automation, and Connected operations. These technologies enable manufacturers to achieve operational excellence, enhance asset efficiency, and ensure sustainable practices.

Benefits include improved efficiency, reduce time to market, cost-effectiveness, and profitability through optimized processes. Additionally, these factories enhance process robustness, improved Safety , Enhance Supply chain , cut costs in inventory and maintenance, and lower the carbon footprint.

The TRU Smart Factory Assessment Framework helps manufacturers gauge their maturity in digital manufacturing and helps in identifies gaps . It provides a roadmap to achieve peak IT-OT excellence, ensuring enhanced efficiency, sustainability, and production maximization.