How many of the PLM capabilities available today do companies actually use?

The answer is sobering...

When the concept of Product Data Management (PDM) was introduced in the early 1980s, the scope of available systems was limited to CAD data management, document management and BOM management. And by 1999, when the term Product Lifecycle Management (PLM) was introduced, most systems also had some type of workflow management capability.

Since then PLM vendors have introduced a host of new modules and functionalities. Today's leading PLM systems offer most of the overall PLM capabilities illustrated in the Birlasoft PLM Advisors PLM Framework below.

Figure 1: Birlasoft PLM Advisors PLM Framework

But how many of the available PLM capabilities do companies actually use today? The answer is quite sobering: Most companies do not use much more PLM functionality today than what was available in 1999.

In most companies the implemented scope islimited to the foundational capabilities of Document File Management, Component or Ingredient Management and BOM Management (as shown in the illustration above) with some additional workflow functionality.

"Most companies do not use much more PLM functionality today than what was available in 1999."

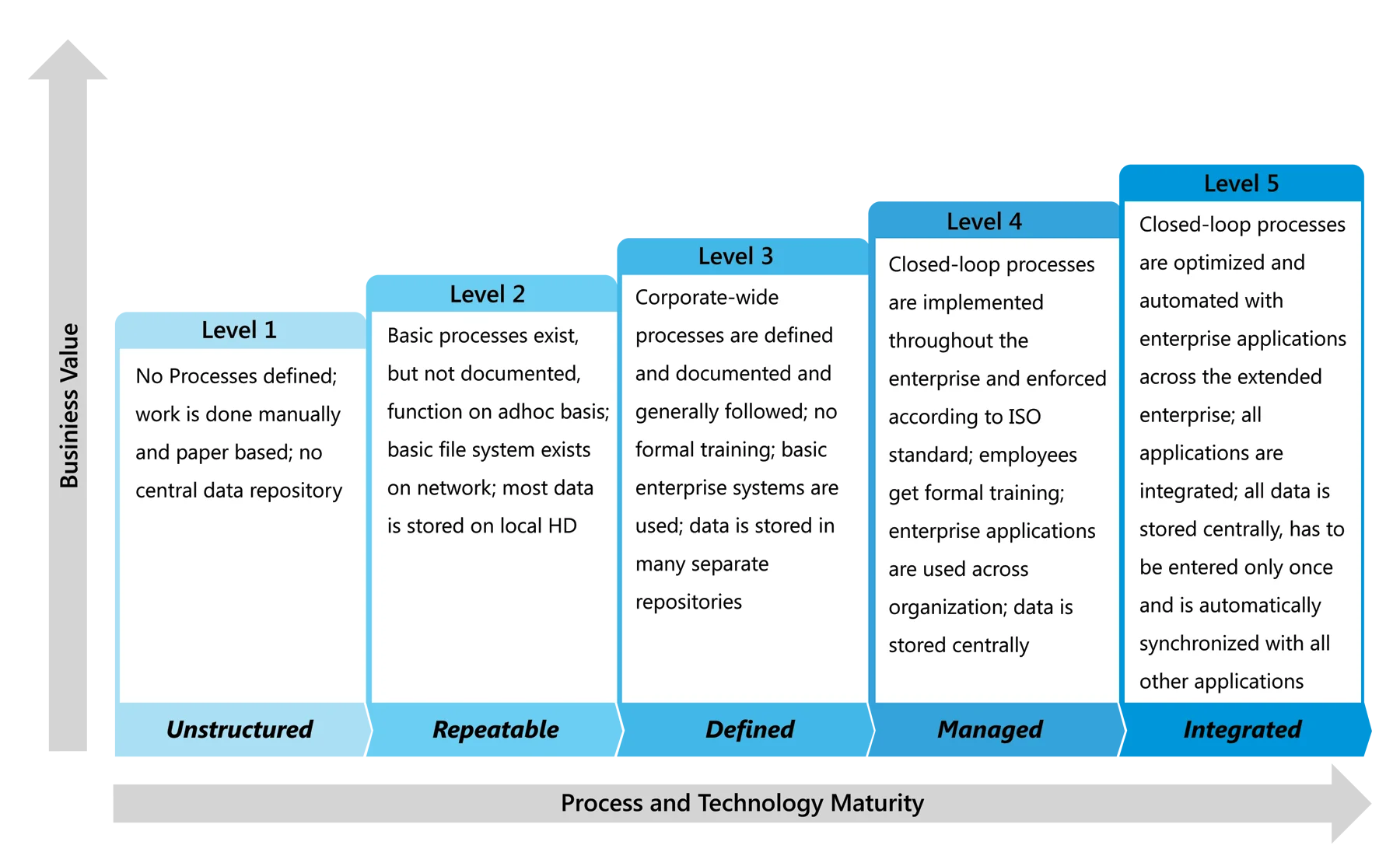

Most companies also use PLM only in a limited part of the organization to manage a subset of the overall product data. Today PLM is used predominantly in engineering and related functions to manage engineering related data, such as CAD models, drawings, engineering BOMs and other design documents. Unfortunately this only scratches the surface of what modern PLM systems offer and consequently of what is possible with PLM today. Using the Birlasoft PLM Advisors PLM Maturity Model illustrated below, most companies would fall somewhere between maturity levels 2 and 3 today.

Figure 1: Birlasoft PLM Advisors PLM Framework

What does this mean for most companies that use PLM today? It means a tremendous loss of business value and a very low return on their current investment in PLM. Capital is invested in a tool whose functionality is only marginally utilized. It is similar to buying a Ferrari and driving it around only on narrow neighborhood roads.

"What does this mean for most companies that use PLM today? It means a tremendous loss of business value and a very low return on their current investment in PLM."

In most instances fortunately it doesn't require much to get significantly more out of the current PLM system. Often with only a little incremental effort and investment in optimizing business processes and configuring the system, the same software licenses can be used to manage all product related data and information across the entire organization, including CAD, CAM and CAE data, all product, quality and manufacturing related documents, engineering and manufacturing BOMs (EBOMs and MBOMs), ideas, requirements, projects, resources, software and electronics, to automate company-wide business processes and to integrate with the company's ERP and other business systems.

"Most companies using PLM today would without doubt benefit greatly from an expanded use of the existing PLM software, both in terms of functionality as well as organizational reach."

A PLM Capability & Maturity Assessment can quickly identify areas with the biggest improvement potential and gaps to industry best practices and best-in-class technology utilization and lay the foundation to get more out of your PLM system.

About Author

Andreas Lindenthal leads the PLM Advisors practice at Birlasoft. He is a passionate thought leader and recognized industry expert with over 25 years international, hands-on professional experience in innovation, New Product Development (NPD), and Product Lifecycle Management (PLM). He has served over 50 leading global companies across various industries to sustainably improve their business results by helping them to drive innovation, increase productivity, shorten time-to-market, reduce costs, ensure compliance and improve product quality through the optimization and resourceful utilization of innovation, NPD and PLM practices, processes and technologies.

Follow Andreas on